Anthu ambiri sangadziwe momwe angagwiritsire ntchito makina oyika, kufotokozera mfundo zamakina oyika, komanso magwiridwe antchito otetezeka. Makampani a XLIN akhala akukhudzidwa kwambiri ndi makina oyika makina kwa zaka 15. Lero, ndikugawana nanu mfundo yogwirira ntchito komanso njira yotetezeka ya makina oyika.

Makina oyika: omwe amadziwikanso kuti "makina okwera" ndi "Surface Mount System", pamzere wopanga, amakonzedwa pambuyo pa makina operekera kapena makina osindikizira pazenera, ndipo makina okwera pamwamba amayikidwa ndikusuntha mutu wokwera. Chipangizo chomwe chimayika zinthu pa PCB pads. Makina oyika ndi ophatikiza makina, magetsi, kuwala ndi ukadaulo wowongolera makompyuta. Kupyolera mu kuyamwa, kusamuka, kuyika, kuyika ndi ntchito zina, zigawo za SMC / SMD zitha kulumikizidwa mwachangu komanso molondola pamalo osankhidwa a PCB popanda kuwononga zigawo ndi bolodi losindikizidwa.

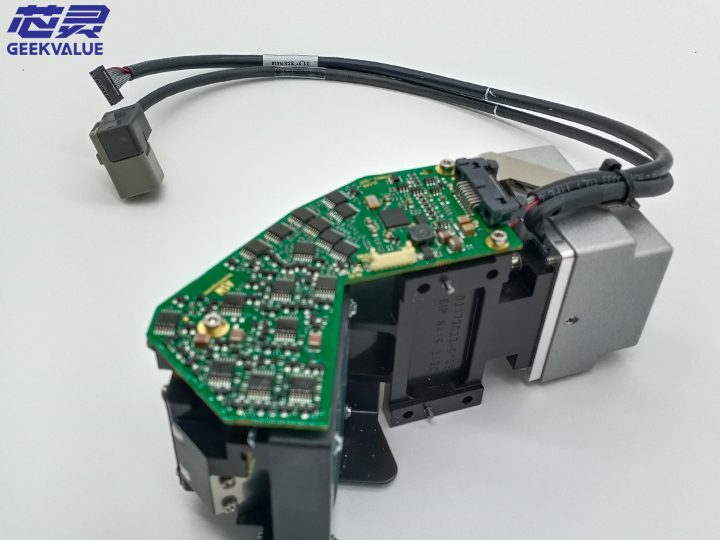

Pali njira zitatu zokhazikitsira zida zamakina pamakina oyika: mechanical centering, laser centering ndi visual centering. Makina oyika amakhala ndi chimango, xy motion mechanism (ball screw, linear guide, drive motor), mutu woyika, component feeder, PCB yonyamulira makina, chipangizo cholumikizira chipangizo, ndi makina owongolera makompyuta. Kuyenda kwa makina onse kumazindikiridwa makamaka ndi makina a xy movement, mphamvu imafalitsidwa ndi wononga mpira, ndipo kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake. Fomu yopatsirayi sikuti imangokhala ndi kukana pang'ono, kapangidwe kakang'ono, komanso kuyendetsa bwino kwambiri.

1. Pali mitundu iwiri yamakina oyika: yamanja komanso yodziwikiratu.

2. Mfundo Yofunika Kwambiri: The arch-type component feeder ndi substrate (PCB) ndizokhazikika, ndipo mutu woyika (woikidwa ndi ma nozzles angapo akuyamwa vacuum) umayenda mmbuyo ndi mtsogolo pakati pa wodyetsa ndi gawo lapansi kuti achotse zigawozo kuchokera ku feeder. Sinthani malo ndi momwe akulowera, ndiyeno kumamatira pa gawo lapansi.

3. Chifukwa mutu wa chigamba umayikidwa pa X / Y kugwirizanitsa mtengo wosuntha wa mtundu wa arch, kotero umatchedwa dzina.

4. Njira yosinthira malo ndi malangizo a zigawo za mtundu wa arch mounter: 1), sinthani malo ndi makina opangira makina, ndikusintha njirayo pozungulira phokoso loyamwa. Zolondola zomwe njirayi ingathe kukwaniritsa ndi yochepa, ndipo zitsanzo zamtsogolo sizigwiritsidwanso ntchito.

5. Laser kuzindikira, X/Y kugwirizanitsa dongosolo kusintha malo, kuyamwa nozzle kasinthasintha kusintha malangizo, njira imeneyi akhoza kuzindikira chizindikiritso pa ndege, koma sangathe ntchito gululi mpira anasonyeza chigawo BGA.

6. Kuzindikirika kwa kamera, X/Y imagwirizanitsa malo osinthika, kusintha kozungulira kwa nozzle, nthawi zambiri kamera imakhala yosasunthika, ndipo mutu woyikapo umawulukira pa kamera kuti izindikirike, zomwe zimatenga nthawi yayitali kuposa kuzindikira kwa laser, koma imatha kuzindikira. chigawo chilichonse, komanso palinso zokhazikitsidwa Njira yozindikiritsa kamera yozindikirika pakuthawa imakhala ndi nsembe zina potengera kapangidwe ka makina.

7. Mu mawonekedwe awa, chifukwa cha mtunda wautali wa mutu wa chigamba ukusunthira mmbuyo ndi mtsogolo, liwiro limakhala lochepa.

8. Nthawi zambiri, ma nozzles angapo akuyamwa vacuum amagwiritsidwa ntchito kunyamula zinthu nthawi imodzi (mpaka khumi) ndipo makina opangira mipanda iwiri amagwiritsidwa ntchito kuti awonjezere liwiro, ndiye kuti, mutu woyika pamtengo umodzi ukutola zinthu, pamene mutu woyika pa mtanda wina ukumamatira Kuyika kwa chigawo kumakhala mofulumira kuwirikiza kawiri ngati dongosolo la mtengo umodzi.

9. Komabe, muzogwiritsira ntchito, zimakhala zovuta kukwaniritsa chikhalidwe chotenga zipangizo panthawi imodzi, ndipo mitundu yosiyanasiyana ya zigawozi iyenera kusinthidwa ndi ma nozzles osiyana siyana a vacuum, ndipo pali kuchedwa kwa kusintha kwa ma nozzles.

10. Chodyetsa chamtundu wa turret chimayikidwa pa ngolo imodzi yogwirizanitsa zinthu zosuntha, gawo lapansi (PCB) limayikidwa pa tebulo la ntchito lomwe limayenda mu dongosolo la X / Y logwirizanitsa, ndipo mutu woyikapo umayikidwa pa turret. Ikagwira ntchito, zinthu Galimoto imasuntha chophatikizira kupita kumalo onyamula, mphuno yoyamwa vacuum pamutu wa chigamba imanyamula zida zomwe zili pamalo onyamula, ndikuzungulira pamalo onyamula kudzera pa turret (180). madigiri kuchokera pamalo onyamula). Sinthani malo ndi malangizo a zigawozo, ndikuyika zigawozo pa gawo lapansi.

11. Njira yosinthira pagawo la gawo ndi malangizo: kuzindikira kwa kamera, X / Y kugwirizanitsa mawonekedwe a dongosolo, kuyamwa nozzle kudzizungulira kozungulira kolowera, kamera yokhazikika, kuyika mutu ukuwuluka pa kamera kuti izindikirike.

Kuphatikiza apo, makina oyika amayika magawo ofunikira monga ma shaft okwera, ma lens osuntha / osasunthika, zonyamula ma nozzles ndi zodyetsa. Masomphenya a makina amatha kuwerengera makonzedwe apakati pazigawo zolembera, kukhazikitsa ubale wosinthika pakati pa makina olumikizirana ndi makina opangira ma PCB ndi zida zokwera, ndikuwerengera zolumikizira zolondola zamakina oyika. Mutu woyika umagwira mphuno yoyamwa, ndikuyamwa zigawozo kumalo ofananirako malinga ndi mtundu wa phukusi, chiwerengero cha chigawo ndi magawo ena a zigawo zomwe zimatumizidwa kunja; mandala osasunthika amazindikira, amazindikira ndikuyika zigawo zoyamwa molingana ndi pulogalamu yowonera; ndikudutsa pamutu wokwera mukamaliza Kwezani zida pa PCB pamalo okonzedweratu. Zochita zingapo monga chizindikiritso cha chigawo, kuyanjanitsa, kuzindikira, ndi kukhazikitsa zonse zimamalizidwa ndi dongosolo lowongolera pambuyo poti kompyuta yamakampani ipeza deta yoyenera molingana ndi malangizo ofananira.

Makina oyikapo ndi chipangizo chomwe chimagwiritsidwa ntchito poyika zida zothamanga kwambiri komanso zolondola kwambiri, ndipo ndi zida zofunika kwambiri komanso zovuta pakupanga konse kwa SMT. Mounter ndi zida zoyika chip zomwe zimagwiritsidwa ntchito popanga ma SMT. Makina oyika ndikuyika makina oyika bwino pamalo ofananirako, ndikumata ndi guluu wofiira wophimbidwa kale ndi phala la solder, ndiyeno kukonza makina oyika pa PCB kudzera mu uvuni wobwereranso.

Kugwiritsa ntchito kotetezeka kwa makina oyika kuyenera kutsatira malamulo ndi njira zotsatirazi:

1. Mphamvu iyenera kuzimitsidwa poyang'ana makina, kusintha magawo kapena kukonzanso ndi kusintha kwa mkati (kukonza makinawo kuyenera kuchitidwa ndi batani ladzidzidzi losindikizidwa kapena kudulidwa mphamvu.

2. Pamene "kuwerenga kogwirizanitsa" ndikusintha makina, onetsetsani kuti YPU (programming unit) ili m'manja mwanu kuti muthe kuyimitsa makina nthawi iliyonse.

3. Onetsetsani kuti zida zotetezera "interlock" zimakhalabe zogwira ntchito kuti zitseke nthawi iliyonse, ndipo kuyang'anitsitsa chitetezo cha makina sikungathe kudumpha kapena kufupikitsidwa, mwinamwake n'zosavuta kuyambitsa ngozi zaumwini kapena makina.

4. Panthawi yopanga, wogwiritsa ntchito mmodzi yekha amaloledwa kugwiritsa ntchito makina amodzi.

5. Pa ntchito, onetsetsani kuti ziwalo zonse za thupi, monga manja ndi mutu, zili kunja kwa makina osuntha.

6. Makinawa ayenera kukhazikika bwino (okhazikika, osalumikizidwa ndi waya wosalowerera).

7. Osagwiritsa ntchito makinawo mu mpweya kapena malo akuda kwambiri.

Nthawi yotumiza: Dec-17-2022